AZ Tank Eductors are economical and energy conservative mixing devices for tank agitation, multiple liquid mixing and suspending solids in vessels and tanks. The AZ Tank Eductors utilize the Bernoulli Principle in generating a high velocity to produce a low pressure region.The AZ Tank Eductor is inexpensive in price and conserves energy in that three times the fluid that passes through the nozzle is drawn through the induction ports, entrained and circulated into the tank as a tight plume, producing large scale turbulence.

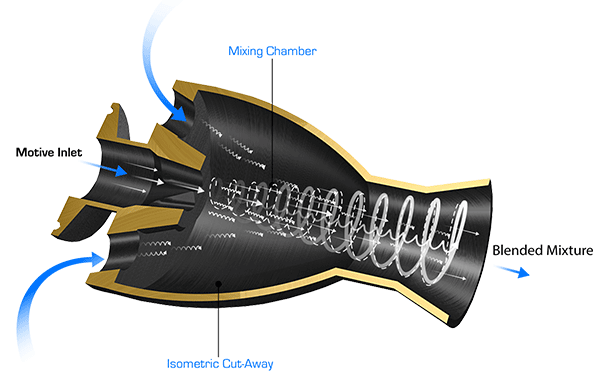

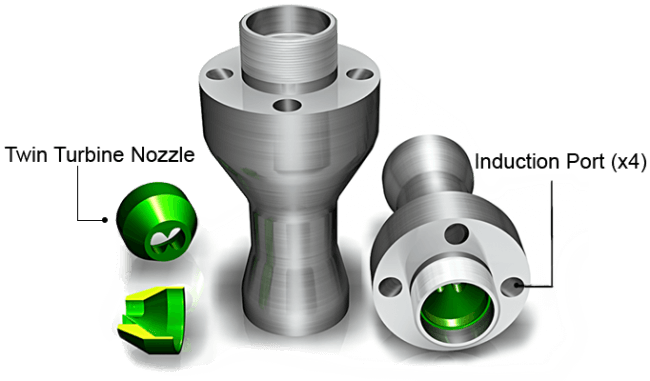

In operation, pump pressure is converted into a high velocity jet stream as the fluid enters a unique nozzle orifice configuration, the issuing jet stream generates a low pressure region in the tank, drawing and entraining fluid from the surrounding liquid or slurry. The volume circulating rate is four times the feed rate.

AZ Tank Eductor Features:

- Venturi Principle

- No moving parts

- Constructed in 304 and 316 S.S.

- Near perfect vacuum at 40 PSI motive pressure

- Blending powders with liquids

- Stainless Steel construction

AZ Tank Eductor Benefits:

- Energy conservation (four times the feed rate is the circulating rate)

- Stabilizes emulsions

- Rapidly mixes multiple liquids

- Suspends solids

- Manifold configurations to accommodate tank size and shape

- Rapid chemical reaction

- Slurry mixing/shearing

- Prevent liquid stratification

Brochures

Please click on the corresponding link below to access a PDF file of our AZ Tank Eductor Brochure.

Fig. 1 AZ Tank Eductor – Model C-TE-3-MT-01

Fig. 2 Illustrates uniform mixture from induction ports and motive feed inlet. Model C-TE-1-S-01

Please contact our sales team to learn more about our AZ Tank Eductors and our Pilot Study Program.

Patent No. 8,622,715

AZ Tank Eductor Pictures

Applications

Below are some common applications with which we have achieved optimal results. This is not an inclusive list, so if you do not see your specific ingredient listed below, please let us know and we will be glad to discuss it further. Contact Us!

| A – F | G – Pol | Pot – Z |

|---|---|---|

| Ammonium Acetate | Gelatines | Potassium Acetates |

| Ammonium Silicate | Gluten | Potassium Aluminum Silicate |

| Anti-caking Agents | Glycerol | Protein Powders |

| Anti-foaming Agents | Gravies | Resins |

| Barley Flour | Guar Gum | Sodium Acetate |

| Bentonite | Gum Arabic | Sodium Aluminum Phosphate |

| Biopolymers | Hard-to-mix Ingredients | SCMC (Sodium Carboxymethylcellulose) |

| Calcium Bisulfate | HEC (Hydroxy Ethyl Cellulose) | Sodium Citrates |

| Calcium Carbonates | HEMC (Hydroxy Ethyl Methyl Cellulose) | Sodium Gluconate |

| Calcium Citrates | Hydrocolloids | Sorbitan (Emulsifier) |

| Calcium Formate | Hydroxypropyl Cellulose | Sulfuric Acid |

| CMC (Carboxymethylcellulose) | Lime | Starches |

| Carrageenan (Polysaccharides) | Magnesium | Sugar and Sugar Substitutes |

| Caropol | Magnesium Stearate | Tara Gum |

| Citric Acid | Milk Powder | Talc |

| Clays | Mineral Salts | Thickeners |

| EDTA | Oils and Fats | Vegetable Gums |

| Emulsifiers | Pectins | Wheat Flour |

| Flavours | Polymers | Xanthan Gum |

| Flocculants | Polysorbates (Emulsifiers) | Zinc Acetate |

Performance

Please click on the corresponding link below to access a PDF file of our AZ Tank Eductor Performance Chart, sizes (0.50″) to (2.00″).

0.5 INCH TO 2 INCH:

AZ Tank Eductor Performance Chart

To learn how our products can lower your costs and improve the quality of your products, contact us for more information!