The AZ Mixing Eductor can provide the required energy to accomplish proper mixing, hydration and dispersion utilizing a conventional centrifugal pump or rotary gear pump. The AZ Eductor does not use mechanical shear to achieve uniform hydration and dispersion.

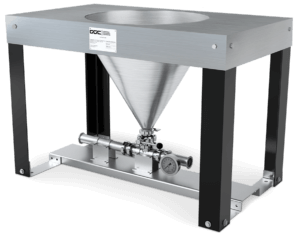

AZ Mixing Eductor Features:

- No moving parts

- Easy to disassemble and clean

- CIP capability

- Compact

- Light weight

- Stainless Steel construction

AZ Mixing Eductor Benefits:

- Rapid dispersion, hydration and particle solubility

- High-speed dosing rate

- Prevents lumps, “fish-eyes,” and microgels

- Uniform blend with polymers, starches, emulsions, clays, pigments, gums, and hydrocolloids.

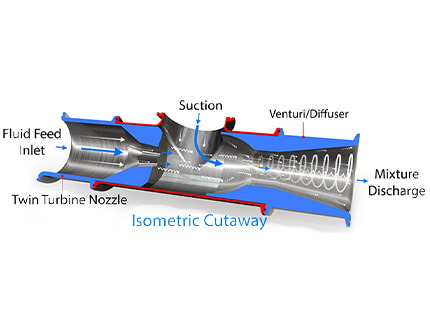

The AZ Mixing Eductor has a non-circular nozzle that generates twin geometrically and opposing downstream vortices. The twin vortices interact with each other’s overlapping axes. The overlapping axes influence fluid stretching and folding. During the stretching, interfacial contact exposes individual strands that promote rapid hydration and the folding motion uniformly disperses the slurry. The dynamic interfacial contact in mixing will enhance the stability of the slurry.

Please contact our sales team to learn more about our AZ Mixing Eductors and our Pilot Study Program. Patent No. 8,622,715

Fig. 3 Twin Turbine Nozzle Insert

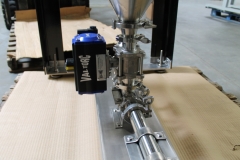

Fig. 3 Twin Turbine Nozzle InsertAZ Mixing Eductor Pictures

AZ Mixing Eductor Performance Charts

Please click on the corresponding links below to access a PDF file of our AZ Mixing Eductor Performance Charts, sizes (1.0″) to (3.0″).

AZ Mixing Eductor – 1 Inch to 3 Inch

AZ Mixing Eductor – 4 Inch

To learn how our systems can lower your costs and improve the quality of your products, contact us for more information!

AZ Mixing Eductor Applications

Below are some common applications with which we have achieved optimal results. This is not an inclusive list, so if you do not see your specific ingredient listed below, please let us know and we will be glad to discuss it further. Contact Us!

| A – F | G – Pol | Pot – Z |

|---|---|---|

| Ammonium Acetate | Gelatines | Potassium Acetates |

| Ammonium Silicate | Gluten | Potassium Aluminum Silicate |

| Anti-caking Agents | Glycerol | Protein Powders |

| Anti-foaming Agents | Gravies | Resins |

| Barley Flour | Guar Gum | Sodium Acetate |

| Bentonite | Gum Arabic | Sodium Aluminum Phosphate |

| Biopolymers | Hard-to-mix Ingredients | SCMC (Sodium Carboxymethylcellulose) |

| Calcium Bisulfate | HEC (Hydroxy Ethyl Cellulose) | Sodium Citrates |

| Calcium Carbonates | HEMC (Hydroxy Ethyl Methyl Cellulose) | Sodium Gluconate |

| Calcium Citrates | Hydrocolloids | Sorbitan (Emulsifier) |

| Calcium Formate | Hydroxypropyl Cellulose | Sulfuric Acid |

| CMC (Carboxymethylcellulose) | Lime | Starches |

| Carrageenan (Polysaccharides) | Magnesium | Sugar and Sugar Substitutes |

| Caropol | Magnesium Stearate | Tara Gum |

| Citric Acid | Milk Powder | Talc |

| Clays | Mineral Salts | Thickeners |

| EDTA | Oils and Fats | Vegetable Gums |

| Emulsifiers | Pectins | Wheat Flour |

| Flavours | Polymers | Xanthan Gum |

| Flocculants | Polysorbates (Emulsifiers) | Zinc Acetate |